18507999558

18507999558

Search

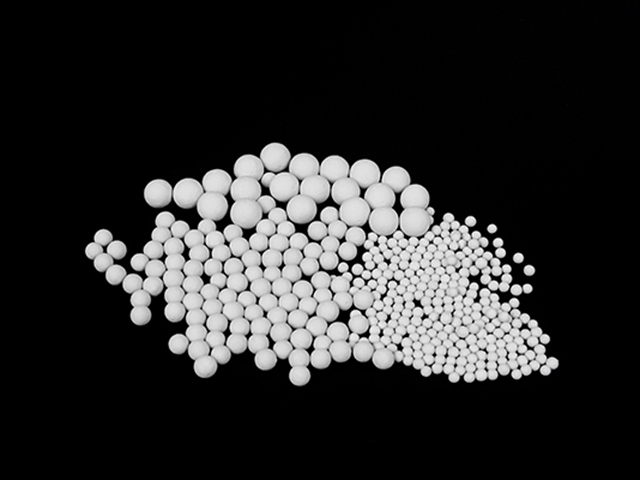

Inert alumina spheres (catalyst proppant) are widely used as fillers for catalyst carriers in the world due to their excellent stability. Produced from high quality chemical porcelain clay materials, they have excellent stability, high mechanical strength and thermal shock resistance, which makes them ideal for supporting all types of catalysts. It is widely used in petroleum, chemical industry, chemical fertilizer, natural gas and environmental protection industries. It is used as covering and supporting material of catalyst in reactor and packing of tower. It has the characteristics of high temperature and high pressure resistance, low water absorption and stable chemical properties. Can withstand the corrosion of acid, alkali and other organic solvents, and can withstand temperature changes during production. Its main role is to increase the gas or liquid distribution point, support and protect the strength of the active catalyst is not high.

● Inert alumina ball is a new type of high strength, high voidage support, cover and protection of catalyst for spherical support protection packing.

● High mechanical strength, high temperature resistance, oxidation resistance, wear resistance, strong acid and alkali chemical corrosion, excellent cold and heat resistance and low chemical activity. Contains a large number of networked needle-like mullite and corundum crystals and some residual quartz, with dense sintering, hard texture and no pulverization.

● Has excellent chemical corrosion resistance: in addition to hydrofluoric acid, can resist all inorganic acid and organic acid and all acid gas, neutral gas. Unless the product needs to be cleaned or replaced when it is polluted by impurities in the raw material gas and liquid, the product itself will not have any problems when used as catalyst covering, proppant and protective agent in the chemical process equipment, and its service life is guaranteed to be more than 10 years.

indicators | The numerical |

Bibulous rate | <0.5 |

The mass density | 1.35-1.4 |

True proportion | 2.3-2.4 |

Void fraction | 40 |

Operating temperature | 1100 |

Mohs hardness | >6.5 |

Acid degree | >99.6 |

Alkali degree | >85 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province