18507999558

18507999558

Search

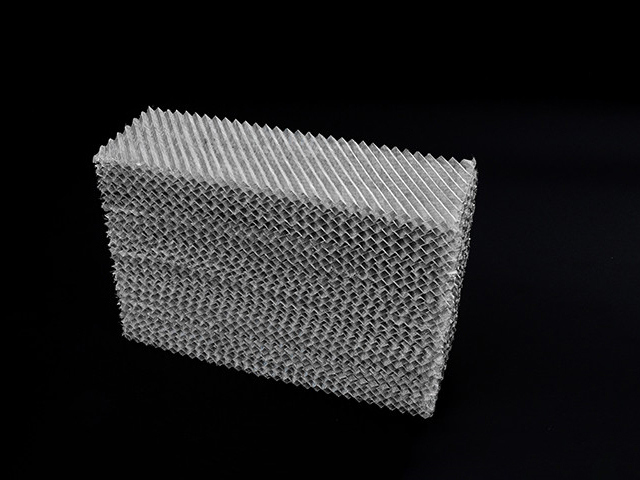

The wire mesh corrugated packing is assembled from stainless steel wire mesh corrugated sheet. The packing forms a uniform geometric pattern arrangement in the tower, which defines the steam and liquid flow path and improves the phenomenon of trench flow and wall flow. The corrugated direction of the mesh and the axis of the tower into a certain inclination Angle is generally 30 and 45°. Because of the capillary effect of the screen, the surface area has more wettability, low pressure drop and less liquid holding capacity, so it has a very high separation efficiency. It is suitable for refractory and heat sensitive systems. Widely used in petrochemical (such as refinery catalytic cracking extraction section), chemical fertilizer, natural gas, biochemistry, environmental engineering and other fields. The diameter of the tower equipment is up to 6 meters, and the separation performance is better than that of the metal orifice corrugated packing.

Wire mesh packing is suitable for a variety of precision separation, fine separation, high purity separation, cryogenic separation, air separation and other occasions. Each meter of packing layer can provide 3~12 engineering theoretical plates, so that the tower height can be greatly reduced. For large liquid-gas ratio system, strong corrosive system, dirty plugging system, high surface tension and high viscosity system, the use should be careful.

● Simple structure, light weight, large porosity, small pressure drop, large contact surface area, high defoaming efficiency,

● Tasteless, low density, strength, stiffness, hardness and heat resistance are better than low pressure polyethylene, can be used at about 100 degrees.

● Has good electrical properties and high frequency insulation is not affected by humidity, but low temperature brittle, not wear-resistant, easy to aging.

| model | Specific surface area | Void fraction | The hydraulic diameter | Theoretical plate number | The pressure drop | Packing factor |

| mm | m2/m3 | p/m | % | Mpa/m | kg/m | |

| 700Y | 4.3 | 700 | 8-10 | 87 | 4.5-6.5X10-4 | 1.3-2.4 |

| 500Y | 6.3 | 500 | 4.5-5.5 | 95 | 3X10-4 | 2 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province