18507999558

18507999558

Search

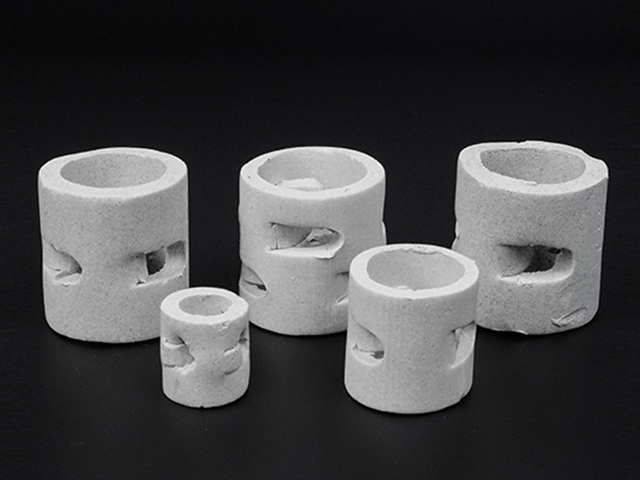

Ceramic pall ring is the improved product ceramic raschig ring, ceramic pall ring added weeks wall open window design, the structure design than raschig ring increases the specific surface area and porosity, product ceramic pall ring gap uniform distribution, greatly improving the distribution of the fluid, is better than ceramic raschig ring with the gap rate and lower pressure drop.

Ceramic pall ring is because its material is ceramic, so we can call him ceramic pall ring, its raw materials mainly, suzhou soil, soil in guizhou, kaolin and other local clay ore, through raw material selection, ball mill grinding, mud filter into soil, vacuum pug equipment, then forming, into the drying chamber, then, high temperature sintering, such as production process. Ceramic raschig ring packing on the basis of pall ring packing from r&d and come out a hole ceramic packing, its diameter and height are equal, it's up and down two floors are open hole, like we open the window, this structure is largely improved the distribution of gas and liquid, make full use of its internal surface area, making it the gas and liquid in the packing tower, can free through from the hole.

Ceramic pall ring as opening ring packing, its each layer hole with 5 ligule, each bend in the tongue lobe point to the ring, the location of the two floors up and down hole is contrary to stagger, ordinary large opening area outside, about 30% of the total area of the ring wall ceramic pall ring made of packed tower of gas and liquid can pass through hole is comfortable, improved the gas-liquid dispersion, energetic application of ring in appearance.

● ceramic pall ring has excellent acid resistance and heat resistance, can and can resist the corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature environment, so its use range is very wide.

● Ceramic Ball ring can be used in drying tower, absorption tower, cooling tower, washing tower in the chemical industry, metallurgy industry, coal and gas industry, industrial oxygen production industry, etc.

● Ceramic pall ring packing is a tower filling material, with acid and heat resistance and high and low temperature resistance, anti-aging characteristics, in addition to hydrofluoric acid (HF) in addition to a variety of inorganic acid, organic acid and organic solvent corrosion, can be used in a variety of high and low temperature occasions.

● ceramic pall ring after sintering ceramic, so it has acid-resistant and heat-resistant performance, it is widely used in metallurgy, chemical industry, chemical fertilizer, acid, gas, oxygen, pharmaceutical and other industries in the scrubbing tower, cooling tower, recovery acid tower, desulfurization tower, drying tower and absorption tower, regeneration tower wash tower absorption tower cooling tower, drying tower inside

SiO2 + Al2O3 | >92% | CaO | <1.0% |

SiO2 | >76% | MgO | <0.5% |

Al2O3 | >17% | K2O+Na2O | <3.5% |

Fe2O3 | <1.0% | Other | <1% |

size mm | The thickness of the mm | Surface area m2/m3 | Void fraction % | Accumulation number per/m3 | Packing weight kg/m3 |

25 | 3 | 210 | 73 | 53500 | 700 |

38 | 4 | 180 | 75 | 15000 | 650 |

50 | 5 | 130 | 78 | 6800 | 600 |

80 | 8 | 110 | 81 | 1950 | 550 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province