18507999558

18507999558

Search

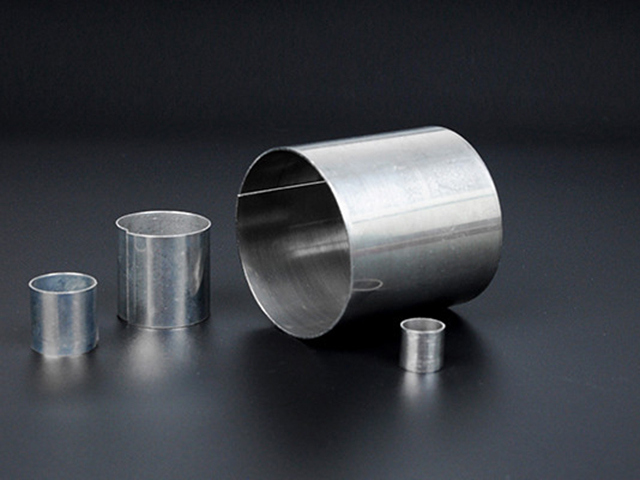

The metal Lasi ring, also known as the Yerrasi ring, has a load capacity of more than 30% relative to other traditional media, almost 70% for a low pressure drop of more than 10% to improve the separation efficiency. The result is lower investment costs in energy. The product is a direct substitute for the widely used Rasch ring packing. The ring has the characteristics of thin wall, heat resistance, large void, large flux, small resistance and high separation efficiency. Applicable to vacuum distillation column, processing heat sensitive, easy to decompose, easy to polymerize, easy to carbon. Therefore, it is widely used in the packed tower of petrochemical, chemical fertilizer, environmental protection and other industries.

Metal Lasi ring material can be a variety of, such as carbon steel, stainless steel 304, 304L, 410, 316, 316L, etc., for choice.

● After the improvement of the metal Rasch ring, the packers such as Pall ring, step ring and conjugate ring were developed. These packers are improved in increasing the mass transfer surface, increasing the mass transfer flux and reducing the mass transfer resistance. Saddle (arc saddle and moment saddle) packing, is a kind of open packing like saddle, in the tower is not easy to form a large number of local non-uniform area, void fraction, small airflow resistance, is a kind of industrial packing with better performance.

● Metal Yilaxi ring fluid resistance is small, flux is large, separation efficiency is high, but not suitable for sediment, easy coking and viscosity of materials, and loading and unloading, cleaning is difficult, the cost is high. Using wire mesh to manufacture packing will undoubtedly increase the specific surface area of packing and reduce the airflow resistance, thus improving the mass transfer efficiency. This kind of filler mesh ring, saddle mesh, corrugated mesh, triangular coil, etc. When designing the packed column, the hydrodynamic performance of the packed column should be considered first, which mainly includes the pressure drop of gas passing through the packed layer, liquid flooding gas velocity, liquid holdup (the volume of liquid held by the packing per unit volume), gas-liquid distribution, etc.

| size | Packing weight | Accumulation number | Specific surface area | Void fraction | Dry packing factor |

| kg/m3 | Per/m3 | m2/m | % | m-1 | |

| 0.3”(8) | 230 | 180000 | 315 | 97.1 | 343.9 |

| 0.5”(13) | 275 | 145000 | 250 | 96.5 | 278 |

| 0.6”(16) | 310 | 145000 | 215 | 96.1 | 393.2 |

| 0.7”(18) | 240 | 45500 | 180 | 97 | 242.2 |

| 1.0”(25) | 220 | 32000 | 150 | 97.2 | 163.3 |

| 1.5”(38) | 170 | 13100 | 120 | 97.8 | 128 |

| 2”(50) | 165 | 9500 | 100 | 97.9 | 106.5 |

| 3”(76) | 150 | 4300 | 80 | 98.1 | 84.7 |

| 3.5”(89) | 150 | 3600 | 67 | 98.1 | 71 |

Copyright © Jiangxi Aite Mass Transfer Technology Co., Ltd. Gan ICP is prepared 2021000504-1

Company address: the intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Pingxiang City, Jiangxi Province